A flap disc is a powerful abrasive tool designed for grinding, smoothing, and finishing surfaces, particularly metals and marble. Mounted on an angle grinder, this dynamic accessory removes burrs, rust, and imperfections, creating a polished, uniform finish. Unlike traditional rigid grinding wheels, flap discs feature layered abrasive flaps that adapt to contours, delivering precision and reducing uneven scratches. In this guide, we’ll explore how flap discs work, their applications, and tips for selecting the right grit to achieve professional results.

Understanding Flap Disc Structure and Design

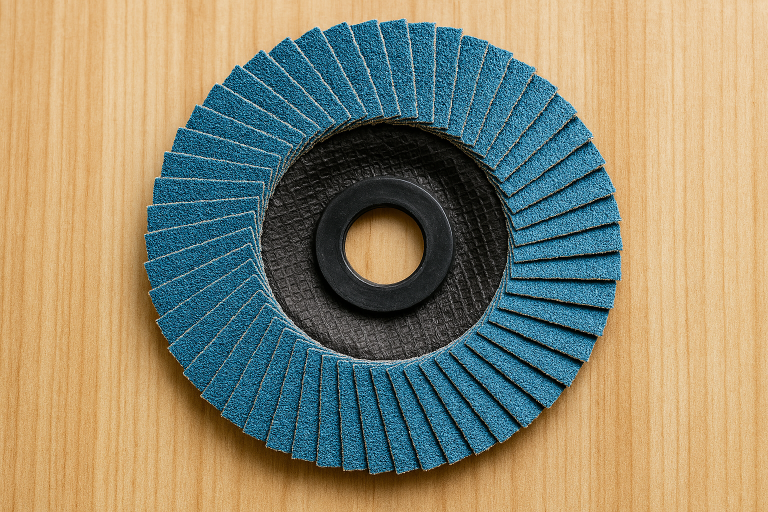

Flap discs are engineered with overlapping abrasive flaps arranged radially around a central hub. Each flap consists of abrasive grains (commonly aluminum oxide or zirconia) bonded to a cloth or polyester backing. These layers are angled to ensure consistent contact with the workpiece, distributing wear evenly and prolonging the disc’s lifespan.

Key Advantages Over Traditional Discs:

- Flexible Contact: The flaps conform to irregular surfaces, ideal for curved or angled edges.

- Reduced Heat Buildup: Intermittent contact prevents overheating, minimizing material warping.

- Versatility: Suitable for both heavy material removal and fine finishing.

Primary Applications of Flap Discs

While flap discs excel in metalworking, their utility spans multiple industries and materials:

- Metal Fabrication:

- Deburring: Smooth sharp edges after cutting or welding.

- Weld Preparation: Clean joints for seamless metal joining.

- Rust Removal: Strip corrosion from steel surfaces before painting or coating.

- Stone and Marble Work:

- Surface Leveling: Eliminate protrusions on marble countertops or tiles.

- Edge Polishing: Create beveled or rounded edges for a refined look.

- Woodworking (Limited Use):

- Tool Maintenance: Sharpen blades or chisels with fine-grit discs.

- Automotive Restoration:

- Paint Stripping: Remove old paint layers without damaging the base metal.

Selecting the Right Flap Disc Grit for Your Project

Grit size determines the aggressiveness of material removal and the smoothness of the finish. Understanding grit numbering ensures optimal results:

- Coarse Grit (40–80):

Ideal for heavy stock removal, weld leveling, or rust cleanup. - Medium Grit (120–180):

Balances material removal and surface preparation for welding or painting. - Fine Grit (220+):

Achieves smooth finishes on metals or polishes stone surfaces.

Pro Tip: Start with a coarse grit for initial sanding and progress to finer grits for finishing. Always match the grit to the material hardness and desired outcome.

Flap Discs vs. Traditional Abrasive Tools

- Grinding Wheels:

- Wheels are rigid and wear down unevenly, while flap discs self-sharpen as layers erode.

- Wheels generate more heat, risking workpiece damage.

- Sandpaper or Belts:

- Flap discs handle curved surfaces better and last longer than flat abrasives.

Safety and Best Practices

- Wear Protective Gear:

- Safety glasses, gloves, and masks guard against debris.

- Check RPM Ratings:

- Ensure the disc’s maximum RPM matches your grinder’s speed.

- Apply Even Pressure:

- Let the tool do the work; forcing it can overheat the material.

- Inspect Regularly:

- Replace discs with torn flaps or uneven wear to maintain balance.

Conclusion: Mastering Flap Disc Techniques

Flap discs are indispensable for achieving flawless finishes in metalwork, construction, and craftsmanship. By selecting the correct grit and mastering safe usage, you’ll enhance efficiency and project quality.